- Delhi Road, Saharanpur, Uttar Pradesh

- GST NO. : 09AAQCS9142J1ZM

- +91-9634261884, +91-7253807000

1 Unit (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Color | Silver |

| Power Source | Electric |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

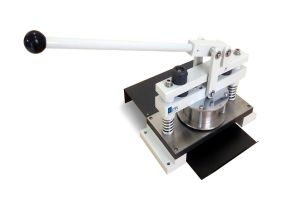

Autoclave and the parts which come into contact with cooking liquor are made of stainless steel.

Digester provided with Digital Temperature Indicator cum controller, Pressure indicator, Safety Valve and sampling valve.

Cooling water trey and bomb opening cabinet for filling and opening after cooking .

Option:

Complete attachment for oxygen injection to the autoclave with NRV and other safety valves

Polyglycol Heating chamber stainless steel double jacketed thermally insulated container,

with easy lid opening and locking mechanism

Autoclaves volume 6 number 2.5 liter and suitable for 300-350 g bone dry wood

MOC SS316 L and rotating in a polyglycol 900 bath

Heating elements: 2 No’s , 7.5 kW each with PID digital temp control to provide

precise heating at temp peak point to select ramp control during cooking

Temperature control range: PID type temp controller with Ramp selection to select several

temp range and time interval ambient to 350 0C with overheating temp protection with alarm indication

Temp of glycol bath and bombs can be check separately

Maximum working pressure: 20 Kg/cm2.

Test pressure: 30 Kg/cm2

Safety valve Make fainger Specially suitable for paper industries raw material

Drum rotation: 2.8 rpm.

Normal working temperature: 170 0C.

Glycol volume required: 90 Liter at customer scope

Chemical Recovery stainless Glycol recovery system using double jacketed column

with cooling water recirculation.

Power supply: 400-440 V, 3 Phase, 17 kW

Provision for taking samples

Autoclave and the parts which come into contact with cooking liquor are made of stainless steel.

Digester provided with Digital Temperature Indicator cum controller, Pressure indicator, Safety Valve and sampling valve.

Cooling water trey and bomb opening cabinet for filling and opening after cooking .