- Delhi Road, Saharanpur, Uttar Pradesh

- GST NO. : 09AAQCS9142J1ZM

- +91-9634261884, +91-7253807000

For PULP Testing

Leading Manufacturers, Exporters and Wholesaler of Canadian Freeness Tester, KCL Hand Sheet Former, Lab Sheet Press, Laboratory Flotation Cell, Laboratory Hydra Pulper, Laboratory Valley Beater, Pulp Disintegrator, Rapid Sheet Dryer, SCA Hand Sheet Former, SR Freeness Tester, Stainless Steel Fiber Classifier and TAPPI Hand Sheet Former from Saharanpur.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Temperature Capacity | Low Temperature |

| Type | Freeness Tester |

| Capacity of the Cylinder | 1000 Ml Above the Screen Plate |

| The Volume in the Bottom | 23.5 ± 0.2ml |

| Slope of the Main Cone | 290 ± 5 min. |

| Orifices Provided in Funnel | Two, One At the Bottom & other On the Side |

| Distance Between the Overflow | 50.8 Mm ± 0.75 Mm Lip of the Tube (inside the Funnel) |

| Size of the Perforations in the Screen Plate | 0.51±.01 Mm Diameter and No of Holes are 97 Per/cm2 (tappi Standard) |

| Compliance to the following International Standards | ISO 5267/2 CPPA C1 BS 6035/2 TAPPI T 227 . |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition: Freeness of pulp is a measure of precisely how rapidly water can drain from a diluted fiber furnishes suspension. The freeness of pulp is designed to give a measure of the rate at which a dilute suspension of pulp (3 g of pulp in 1 L of water) may be drained. The freeness, or drainage rate has been shown to be related to the surface conditions and swelling of the fibers. Besides these factors, the result is dependent also on conditions under which the test is carried out, such as stock preparation, temperature, and water quality.

Standardization : ISO 5267/2 , CPPA C1 , BS 6035/2 , TAPPI T 227 .

Device Description : The freeness tester consists of a drainage chamber and a rate measuring funnel, mounted on a Stainless Steel Shaft Fitted on a Base Plate .

1. The drainage chamber bottom of which contains a perforated brass screen plate and is closed with an air-tight lid, hinged on one side of the cylinder and latched at the other.

2. The lid fitted in such a way that not more than 5 mL of water will flow when the bottom cover is opened at the start of the test.

3. The upper end of the cylinder is closed by a similar lid with hinge and latching mechanisms to provide an air-tight closure by means of a rubber gasket on the inside of the lid. An air-cock is inserted in the center of the upper lid to admit air to the cylinder at the start of a test.

Test Description :

1. Thoroughly clean and wet the freeness tester with distilled or deionized water at the temperature of the stock to be tested.

2. Place the drainage chamber on the upper supporting bracket with its lower lid closed and the upper lid and air-cock open.

3. Place the graduated cylinder in position to receive the discharge from the side orifice, and a container to collect the discharge from the bottom orifice.

4. Thoroughly stir the stock in the bucket to ensure a homogeneous mix and accurately measure 1000 mL into a clean 1-L cylinder. Take its temperature to the nearest 0.5°C .

5. Mix the sample in the graduated cylinder by closing the top of the cylinder with the hand and gently invert the cylinder 180° three times.

6. Pour the stock gently but as rapidly as possible into the chamber. It is imperative that at the end of the pouring, the stock be almost motionless in the chamber. This step is critical .

7. Close the top of the lid and the air-cock. Open the bottom lid. After 5 s from the time the addition of the stock is completed, fully open the air-cock in a single motion.

8. When the side discharge has ceased, record the volume discharged from the side orifice in milliliters to the maximum accuracy possible for the graduate used

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi Automatic |

| Sheet Size | 165mm X 165mm |

| Type | Sheet Forming Machines |

| Country of Origin | India |

| Stock Container and dewatering vessel | Stainless Steel |

| Suction Height | 800 Mm. |

| Application | For the Preparation of Laboratory Sheets of Pulp for Paper Testing |

| Grid Plate with Wire Screen | 100 mesh (ASTM std. )150 mesh (TAPPI std.) , |

| Drainage Time | 3.8 ± 0.2 sec., 20 0C ± 1 0C |

| Standard Accessories | Stirrer, Couch Roll, Couch Plate, 10 Nos. Ss Drying Disks Mirror Polished One Side, 10 Nos. Thermose |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition : when pulp suspension passed through a standard wire mesh fitted on a circular grid plate under standard barometric height to provide the necessary vacuum over the grid plate to form the paper sheet under uniform parameter such as consistency , temperature , water volume is defined as lab hand sheet making.

Device Description : Sheet Former of KCL model is intended for production of laboratory sheets for physical tests The design of the dewatering vessel gives a constant flow across the entire wire, thus permitting extremely uniform sheets. The Sheet Former is easy to install in a laboratory and produces square sheet size 165x165 mm.

Test Description : by opening the hand valve the former column is half filled with water and suspensions, which has been prepared in the disintegrator , and equalizer is added . Then the former column gets filled up until the mark is reached . the agitator is used to swirl the content of the column , once the settling phase is finished , the second hand lever gets moved to open the drainage valve and the water is drained through the forming screen. The freshly formed hand sheet remains on the screen. The former column can then be opened and two blotting papers are placed on the top of wet hand sheet. With the stainless steel roller the sheet is couched and then carefully be removed from the screen and further processed with the sheet press, the drying rings or the speed dryer.

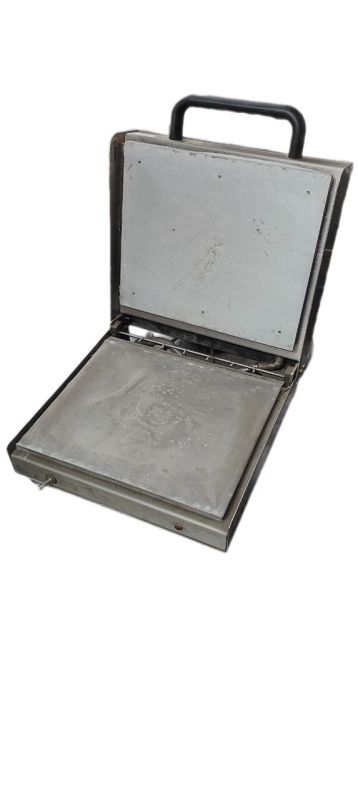

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | STIPL |

| Application | Paper Testing,Pressing and Dewatering Sheet Made On Sheet Making Machine. |

| Country of Origin | India |

| Working Pressure | 7 Kg/cm2 |

| Press Plattens | 350 x 350mm |

| Stroke length | 75 mm |

| Travelling | 210 mm |

| Pressing Load | 16 Kn |

| Pressing Cycle | Two Number Solid Stat Timer for from 0-30 and May Be Set in Seconds, Minutes Hours and 10 Hours. |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Device Description : For pressing and dewatering of the hand sheet quickly made on standard

sheet making apparatus must be pressed in uniform manner for the distribution of pulp across the

area.

The press top made of duralumin for rigidity and lightness is secured by 4 rapid action clamping

and release nuts.

Control panel houses two timers one of 12 min and other of 6 min push button switches and

pressure gauge.

Precision air pressure and air flow regulators are housed in the cabinet.

A fail safe pressure relief valve is fitted to the air storage chamber, which functions

automatically if the inlet supply pressure exceeds the maximum.

Press platens are of stainless steel.

Centering template made of aluminum is supplied to adjust the location of sample sheets

Multi-number samples can be placed simultaneously for pressing. Working pressure 7 Kg/cm2

Test Description : The Sheet Press is operated pneumatically by compressed air supply. The specimen is pressed by gradually raising the rubber diaphragm with compressed air, pushing up the floating square flat press platen with larger area and higher load capacity. The solid state timers provide the timing sequence for dewatering time.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Application | Industrial Use |

| Voltage | 440 V AC |

| Type | Floatation Cell |

| Frequency | 50 Hz |

| Phase | Three Phase |

| Country of Origin | India |

| Container Capacity | 25 Liter with Automatic Foam Removal |

| Speed of Foam Paddle | 10 Revolutions per Minute |

| Drive | Dc Variable Drive |

| Consistency | Upto 2% Stock Consistency |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition : FLOATATION is a physio-chemical process of separating materials. It is based on the phenomenon that separation is achieved by influencing the wettability with water of the particles to be separated. The water repellency of the surface of the particles to be separated is achieved by the addition of special heteropolar chemicals, which deposit on the surface of the particles at the same time the treated particles can deposit on air bubbles that are introduce into the suspension. As a result of buoyancy of the air bubbles the adhering particles are conveyed to the surface of the suspension to concentrate as a forth, which can be removed.

Device Description : The laboratory flotation cell consists of an acrylic glass vessel for 25 liter suspension with 300 mm diameter and a drainage pipe. On top of the vessel there is an automatic foam removal system, driven by a motor with magnetic coupling. On the bottom of the tank there is a self-suction aeration rotor. The air for the aeration rotor is regulated via an air flow meter. The air is guided by a baffle plate.

Test Description : The foam outlet is covered and 25 liter of the suspension are poured into the container. The cover is removed and the motor on top is in place. The chemicals suspensions are added to the suspension and the motor is turned on. Air bubbles from the aeration rotor create a foam, which is taken away by the foam paddles, guided to the central foam outlet and collected in a basket.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Country of Origin | India |

| Usage | For Pulping of Dry Pulp Sample in Laboratory Scale |

| Container Capacity | 10, 30 & 50 litres |

| Consistency | 5% Maximum (higher Consistency Pulper is also Available Consistency Range upto 35% |

| Speed | 500 RPM |

| Belts | Propeller V-belts Drive and a Circulates the Stock Effectively to Disintegrate Material Rapidly |

| Glass Wool | Stainless Steel 316 Vessel Duly Insulated with Glass Wool |

| Power Supply | Electric Motor 3 Phase 440V, AC. |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition : The laboratory hydra pulper is used for the de-fibreing of the virgin and secondary fiber in laboratory trial of different raw material for making pulp to measure properties, before making commercial production . A suitable and standard apparatus for making pulp, minerals fibres pulp like mica, asbestos etc.

Device Description : the unit consists of a pulping container with a rotor at the bottom driven by a V belt in the lower part of the unit . the electric motor has an adjustable frequency convertor to regulate the rotational speed . a ball valve at the bottom drains the pulp . an acrylic cover prevents injuries during the pulping process . A smaller opening in the cover allows extra content during pulping.

Test Description : the pulp is torn out by hand into about 2 x 2 cm large pieces and soaked with water , then the pilper is activated to mix the pulp and take apart the single fibres without destroying their structures to a homogenous suspension

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | STIPL |

| Application | Lab Use,For Beating of Pulp According to Standardized Conditions (360 G). |

| Type | Lab Testing Equipment |

| Country of Origin | India |

| Standards | TAPPI T200 , T205m, ISO5246-1, SCAN C25CPPA C.2 |

| Beater Roll | Made of Heat Treateable Stainless Steel |

| Diameter | 193.8 mm & width 152.4 mm |

| Beater Roll Flybar | Thickness of Each Flybar is 4.8 Mm and with a Brinell Hardness 350 - 400 |

| Beater roll drum speed | 500 rpm |

| Width of the Bed Plate | 159 mm |

| Number of Bed Plate Bars | 7 Bars, Each 3.2 mm Thick Set in Lead 2.4mm Apart with a Brinell Hardness 325-375 |

| Bed Plate Diaphgram | Thickness of 1.6 mm live rubber. |

| Lever Arm | Casted with Dead Weight 5.5 Kgs. |

| Power Supply | 380 V, AC 3 Phase, 1 HP. |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Device Description : The laboratory beater is mounted upon a stainless steel construction. The device itself is entirely made of stainless steel as well. The container is capable of holding a volume of 23 liters , therefore 360g of pulp can be beaten with one process .the rolls including the blade are 152mm wide and have a diameter of 190-194mm . the bed knife consists of seven 3.2mm thick stainless steel blades. The knives and bed of the beater are encased by a tank cover in order to ensure safe handling of device.

Test Description : 360 g of pulp in a suspension is put into a beater. Now the suspension needs to be topped up with water until the whole mixture reaches a volume of 23 liters. Three minutes after starting the device a sample has to be taken , After that a weight of 5.5 kg has to be fixed to the lever in order to start the actual beating process. Samples can be taken at regular intervals and the pulp can be used to be tested for example on freeness or to form test sheets.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Country of Origin | India |

| Construction | Made of Stainless Steel Container An and Aluminimum Fabricated Body |

| Capacity | 2 Litres with for Equally Spaced Spiral Baffles |

| Propeller | The Three Blade Propeller Mounted On a Vertical Shaft as per Standard Radius |

| Cabinet Type | Hinged Top for Quick Opening. |

| Rotational Frequency | 2975 ± 25 rpm |

| Motor | 0.5 KW, 3 Phase, 440V AC |

| Safety System | Double Safety System Permits Start Only When Drive Unit and Vessel are in Correct Working Position |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Device Description : this high quality product is characterized by simplicity of the operation. Only premium stainless steel and aluminum parts are used to manufacture this instrument . the balanced hinged head allows the operator to open the device with only one hand. On the front side of the device there is start and stop button with an adjustable revolution counter , hence is the possibility of exact amount of revolutions needed to disintegrate the pulp.

Test Description : the disintegration pot needs to be filled with water and required amount of pulp. Now the pot can be placed on the disintegrator and the balanced hinged head can be moved down until it catches. preset the amount of revolutions needed for disintegration. After pressing the start button the device will disintegrate the pulp until full amount of revolutions has been accomplished and stops automatically. now the device can be opened and retrieved samples can be taken for further processing.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | SS |

| Color | Silver |

| Power | 800 W |

| Power Source | Electric |

| Automatic | Semi Automatic |

| Voltage | 220V |

| Controller | Thermostat Controller |

| Sheet Width | Max. Width 300 Mm |

| Sheet Length | Max Length 300 Mm |

| Temperature Range | Adjustable Over a Wide Range upto Maximum of 180 0c ± 10 0c |

| Heaters | Flat Electrical Elements Single Phase, 220 V, 400 W Each for Upper and Lower Plates |

| Power Supply | 220 V, Single Phase, 50 Hz |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

The stainless steel Rapid Sheet Dryer is designed for shortening the drying time of wet pulp sheet or paper samples to determining the dry weight or moisture content.

A wet sample is placed between the cover and the heated surface to dry , the temp of the dryer plate is adjustable through thermostat to control the drying condition , after prescribed time the sample can be weighted to determine its moisture contents Square Drying Plates.

Lower plate is lined with wire cloth to lead off the vapour during the drying process.

Provided with over heating protector, Switch provided with indicator lamp.

Upper and lower drying plates are heated with flat electrical elements.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Hydraulic |

| Sheet Size | 165mm Dia = 214 Cm2 Area |

| Trimmed Size | 200cm2 |

| Wire Screen upper | 100 mesh (ASTM std. )150 mesh (TAPPI std.) , |

| Wire Screen support | 20 Mesh |

| Suction Height | 800 mm |

| Stock Container and dewatering vessel | Stainless Steel |

| Drainage Time | 3.8 ± 0.2 sec., 20 0C ± 1 0C. |

| Standard Accessories | Stirrer, Couch Roll, Couch Plate, 16 Nos. SS Drying Disks Mirror polished one side, 17 Nos. Thermose |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition : when pulp suspension passed through a standard wire mesh fitted on a circular grid plate under standard barometric height to provide the necessary vacuum over the grid plate to form the paper sheet under uniform parameter such as consistency , temperature , water volume is defined as lab hand sheet making.

Device Description : Sheet Former of SCA model is intended for production of laboratory sheets for physical tests The design of the dewatering vessel gives a constant flow across the entire wire, thus permitting extremely uniform sheets. The Sheet Former is easy to install in a laboratory and produces square sheet size 165x165 mm.

Test Description : by opening the hand valve the former column is half filled with water and suspensions, which has been prepared in the disintegrator , and equalizer is added . Then the former column gets filled up until the mark is reached . the agitator is used to swirl the content of the column , once the settling phase is finished , the second hand lever gets moved to open the drainage valve and the water is drained through the forming screen. The freshly formed hand sheet remains on the screen. The former column can then be opened and two blotting papers are placed on the top of wet hand sheet. With the stainless steel roller the sheet is couched and then carefully be removed from the screen and further processed with the sheet press, the drying rings or the speed dryer.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Country of Origin | India |

| Usage | For Measuring the Freeness of Pulp |

| Sample | 2 g. Oven Dried |

| Consistency | 0.2% |

| Reproducibility | Approximately 1 0sr |

| Plexiglass Measuring Cylinder | 100 Sec. with Double Graduation On Ccm and 0sr |

| Nozzles | Calibrated Nozzle and screen plate container grip enabling easy removal for cleaning. Nozzle calibra |

| Wiremesh | Standard wire mesh fixing and removing attachment |

| Lift | Semi-Automatic sealing cone lifting arrangement |

| Pulp Volume | 1000ml |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition: Freeness of pulp is a measure of precisely how rapidly water can drain from a diluted fiber furnishes suspension. The freeness of pulp is designed to give a measure of the rate at which a dilute suspension of pulp (3 g of pulp in 1 L of water) may be drained. The freeness, or drainage rate has been shown to be related to the surface conditions and swelling of the fibers. Besides these factors, the result is dependent also on conditions under which the test is carried out, such as stock preparation, temperature, and water quality.

Device Description : The Schopper Reigler Type Beating & Freeness tester measures the drainage of beaten pulp suspension and expressed as SR number.The manual pulley with wire and fixed load system of loading and unloading of the sealing cone ensures a constant lifting rate for the sealing cone during the test

Test Description : The Shopper Reigler Type Beating & Freeness tester measures the drainage capacity of beaten pulp and is universally used to check the progress of beating process. The drainage of pulp suspension is express in SR number.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Application | Testing Use |

| Type | Pulp Testing Instruments |

| Country of Origin | India |

| Material | SS |

| Flow Speed | 10 litre/min OR 11.4 liter/min. |

| Pulp | 10 & 20g (Oven Dried) |

| Required Time for Screening | 20 Min |

| Rpm | 560 rpm |

| Power Supply | Motor 0.25 Hp AC 3 Phase, 60 W per Unit |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Device Description : the Baure Mcnett fibre classifier consists of up to 5 narrow tanks 255mm deep , 127 mm wide and 320mm high, mounted in a cascaded arrangement , with screens of 335cm2 mounted on the flat side . A vertical , cylindrical agitator with short paddles rotates at 580rpm near one semi circular end of each tank . this causes suspension to flow horizontally across the screen and circulate around the tank . an overflow weir is provided at outgoing side of each screen , and a short pipe leads to the next tank with a finer screen at a slightly lower level , or from the last tank to drain away . A flow regulator supplies water at the rate of 11.35 l/m to the first tank. The motion of the water keeps the water from settling and presents them repeatedly to the screens through which they will pass if the length is less than twice the screen opening. The primary unit has an inlet funnel with an overflow and the nozzle for a constant water flow rate. Fractionating unit is completely self contained having its own electric motor for the rotor and is made of non-corrosive material. Fibre collection box with rapid locking device, support wire and suction connection. Interchangeable screens are available with wire of 4, 6, 8, 10, 14, 20, 30, 50, 100 and 200 standard mesh. The screen frames are clamped spring loaded self clamping system. Classifier gives a very low spread in the results with a variation coefficient of less than 1%.

Test Description: With the screens correctly mounted in the tanks press the start button to start the water flow into thje top tank . as soon as the lowest tank starts overflowing , press the stop button again and simultaneously start to pour the prepared sample of 3,333ml with 24 grams of moisture free pulp during the period of 18second in the top tank. Subsequently the flow at the rate of 11,355 l/m into the top tank, the stirrers and the timing of 20minutes are started automatically . A green light shows that the classification is in the process . during this time the drainage cups are furnished with weighed and marked filter papers.

After the test (20 minutes acc to TAPPI and 15 minutes according to SCAN) the water flux is stopped automatically and green light goes out . the stirrers continue running for another 2 minutes until there is no more water to drain away from the lowest tank . now the drain plug and tap below the cup of the first tank is opened and the pump is turned on to allow the contents to drain into the cup. After the tank has been drained the screen and the tank is flushed carefully with the provided hose. When all the tanks are emptied in this way the pads are taken out of the cups and folded in the middle. As much water as possible is removed using a wringer , a blotter or towel . before weighing to within to 0.01 g the pads are dried in an oven at 100*c to constant weight

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Automatic Grade | Semi Automatic |

| Type | Sheet Forming Machines |

| Country of Origin | India |

| Usage | For the Preparation of Laboratory Sheets of Pulp for Paper Testing . |

| Standardisation | TAPPI T 205 , ISO 5269/1 , SCAN C26 |

| Sheet Size | 165mm dia = 214cm2 Area |

| Trimmed Size | 200cm2 |

| Wire Screen (upper): | 100 mesh (ASTM std. )150 mesh (TAPPI std.) |

| Wire Screen (Support) | 20 mesh |

| Suction Height: | 800 mm |

| Drainage Time | 3.8 ± 0.2 sec., 20 0C ± 1 0C. |

| Stock Container and dewatering vessel | Stainless Steel |

| Standard Accessories: | Stirrer, Couch Roll, Couch Plate, . Ss Drying Disks Mirror Polished One Side, Thermosetting Plastic |

| Brand Name | STIPL |

| Technical Specification |

Preferred Buyer From

| Location | Worldwide |

Definition : when pulp suspension passed through a standard wire mesh fitted on a circular grid plate under standard barometric height to provide the necessary vacuum over the grid plate to form the paper sheet under uniform parameter such as consistency , temperature , water volume is defined as lab hand sheet making.

Standardization : TAPPI T 205 , ISO 5269/1 , SCAN C26

Device Description : the sheet former is intended for installation into a laboratory bench (not included). The individual stages are carried out by moving hand levers . Swirling is done with an agitator with perforated bottom plate and the couching is done with the 10kg stainless steel roller (both included in the delivery). Additionaly 10 polished mirror plates and drying rings are included in the delivery for drying . all parts are constructed of corrosion resistant materials

Test Description : by opening the hand valve the former column is half filled with water and suspensions, which has been prepared in the disintegrator , and equalizer is added . Then the former column gets filled up until the mark is reached . the agitator is used to swirl the content of the column , once the settling phase is finished , the second hand lever gets moved to open the drainage valve and the water is drained through the forming screen. The freshly formed hand sheet remains on the screen. The former column can then be opened and two blotting papers are placed on the top of wet hand sheet. With the stainless steel roller the sheet is couched and then carefully be removed from the screen and further processed with the sheet press, the drying rings or the speed dryer.