- Delhi Road, Saharanpur, Uttar Pradesh

- GST NO. : 09AAQCS9142J1ZM

- +91-9634261884, +91-7253807000

1 Unit (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Application | Industrial Use |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Definition : FLOATATION is a physio-chemical process of separating materials. It is based on the phenomenon that separation is achieved by influencing the wettability with water of the particles to be separated. The water repellency of the surface of the particles to be separated is achieved by the addition of special heteropolar chemicals, which deposit on the surface of the particles at the same time the treated particles can deposit on air bubbles that are introduce into the suspension. As a result of buoyancy of the air bubbles the adhering particles are conveyed to the surface of the suspension to concentrate as a forth, which can be removed.

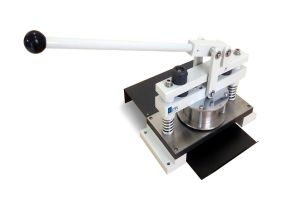

Device Description : The laboratory flotation cell consists of an acrylic glass vessel for 25 liter suspension with 300 mm diameter and a drainage pipe. On top of the vessel there is an automatic foam removal system, driven by a motor with magnetic coupling. On the bottom of the tank there is a self-suction aeration rotor. The air for the aeration rotor is regulated via an air flow meter. The air is guided by a baffle plate.

Test Description : The foam outlet is covered and 25 liter of the suspension are poured into the container. The cover is removed and the motor on top is in place. The chemicals suspensions are added to the suspension and the motor is turned on. Air bubbles from the aeration rotor create a foam, which is taken away by the foam paddles, guided to the central foam outlet and collected in a basket.